PRODUCT INFORMATION

UNIVERSAL series diesel steam boiler (500~2000 KG)

- front page

- product

- steamer

- heat treatment

- UNIVERSAL series diesel steam boiler (500~2000 KG)

Product Information

- heat treatment

-

water treatment

- Arsenic remover

- Desulfurizer

- Deaerator

- Water softener (except calcium and magnesium)

- Carbon filter (removal of chloramines)

- Sand filter (remove impurities)

- Iron remover (removal of iron and manganese)

- RO water purifier

- Pre-backwash filter

- UV ultraviolet sterilizer

- Ion exchange resin

- reverse osmosis membrane tube

- stainless steel filter

- Various tanks for water treatment

- Various application filter media

- 美國 Clack Clark control valve

- 美國 Fleck Control Valve

- 美國 Pentair Control Valve

- 美國 Autotrol Control Valve

- Runxin Control Valve

- Injection treatment

- Technology Development Department

-

brand

- Demo brand

- US DOW

- IDEX USA

- US CLACK

- EMERSON, USA

- American PENTAIR

- SIEMENS Germany

- American PULSAFEEDER

- Denmark DANFOSS

- Thailand HAYCARB

- France SUNTEC

- UK PUROLITE

- Japanese NOP

- Japan OLYMPIA

- Japan KATSURA

- BRAHMA, Italy

- SAGINOMIYA

- HONEYWELL

- AZBIL (YAMATAKE)

- OLTREMARE

- NIPCON

- TROCHOID

- domestic

- EGO

- KATO

- LECIP

- ATS

- JACOBI

- ETATRON

- WAVE CYBER

- BOSCHINI

- NIPPON

- WL

- CASH ACME

- YAZAKI

- RUNXIN

- About | Contact

UNIVERSAL series diesel steam boiler (500~2000 KG)

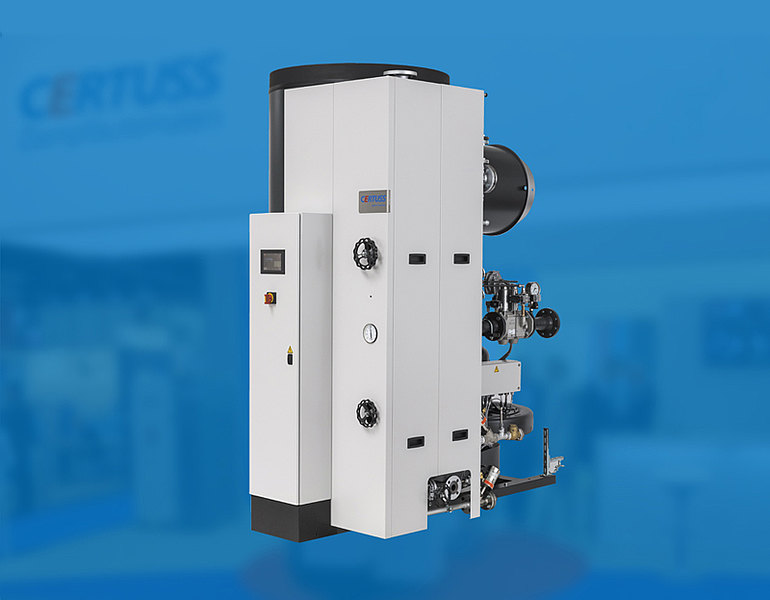

德國 Certuss Original

CERTUSS is a traditional 德國 family business that has been manufacturing steam boilers for over 60 years. For more than 60 years, CERTUSS has earned the trust of small, medium and large well-known companies in more than 100 industries worldwide. When Hans-Joachim Schröder founded the company in 1957, he had ambitious goals: He wanted to manufacture steam boilers that were reliable, low-noise, capable of continuous operation and easy to maintain. Using the principles of the water tube boiler most commonly used in the world for steam generation, he developed the CERTUSS steam boiler. To achieve this goal, the company was founded in 德國 Krefeld and today operates worldwide. The company is committed to providing a clear and clear product line, systematic research and development, and also has a trained team of high-quality professionals to produce products in accordance with the ISO 9001-2015 standard and ASME related regulations. Environmentally friendly, CERTUSS steam boilers efficiently convert gas, oil or electricity into energy. Thanks to their innovative regulated power control, they are ideal for use in industrial and commercial operations. Of course, CERTUSS steam boilers reliably meet current ecological standards. CERTUSS steam boilers are available in the JUNIOR TC series and the UNIVERSAL TC series with steam outputs from 80 to 1,800 kg/h. Depending on the model, oil, gas or combination ignition start is available. The range also includes two models with electric heating. These steam boilers can also be combined in multiple sizes to supply steam economically and reliably. All CERTUSS steam boilers have a vertical design, which greatly reduces space requirements. CERTUSS is a global brand offering high quality coiled tube steam boilers with fast steam production capacity to meet the needs of all steam users. All CERTUSS steam boilers are manufactured with current corresponding pressure equipment standards for European PED regulations PED 2014/68/EU, 美國 ASME and UL coding, Russia, China and more countries etc.

Product advantages:

– Rugged all-steel design

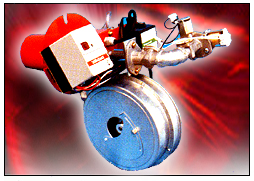

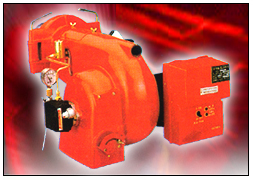

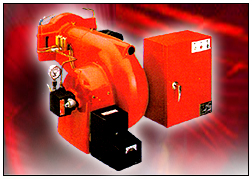

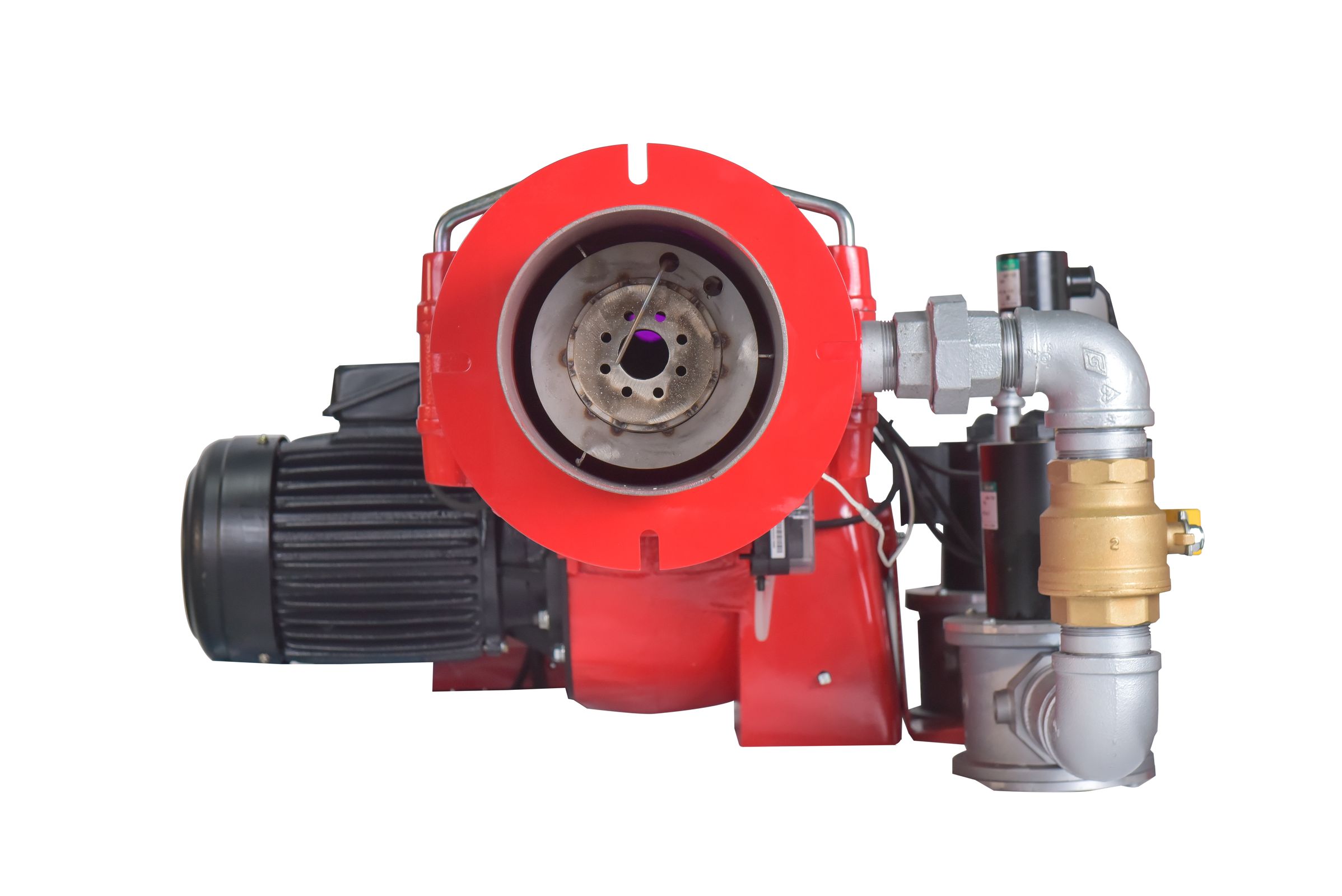

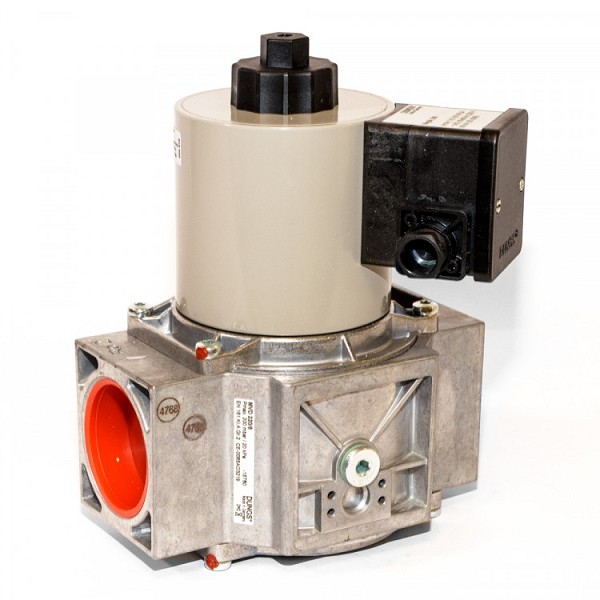

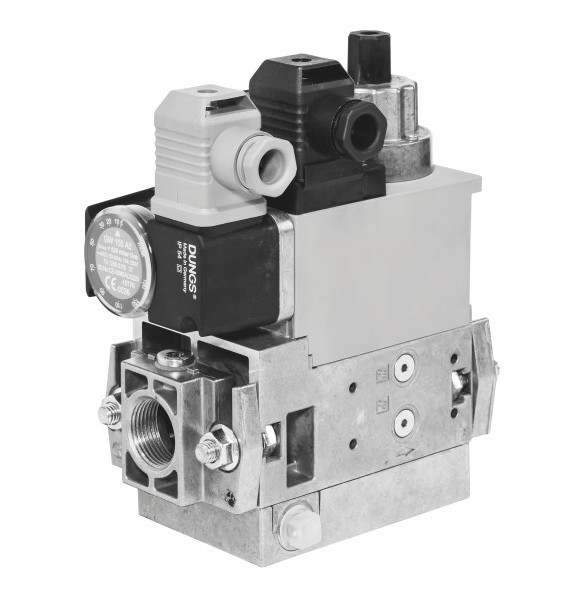

– Optionally equipped with light oil fuel, or a combination of light oil fuel and natural gas

– Burner regulation response to steam pressure is one of the fastest on the market

– Feedwater heated to 85°C to 96°C enters the coil of the heating system from the feedwater tank

– Water softener monitoring equipment ensures constant awareness of water parameters

– Central heating installed vertically with low point purge filtration

– Combustion air intake is from above the boiler and is fan driven to provide clean air at all times

– 3 layers of air circulation and integrated heat recovery – the shell stays cool

– Via steam output, steam can be provided according to application requirements

– Flue gas outlet – deeper forms of heat recovery are possible using a flue gas recovery system

– The blowdown process is carried out with the blowdown tank

– When the pressure is too high, the safety valve will open automatically

– Coil-type rapid steam boiler (fastest instant steam, space-saving vertical design, 德國 safety technology no longer requires a separate boiler room, flexibly adjust your steam needs)

– Thermal efficiency (high energy efficiency, standard thermal efficiency level > 93%, through CERTUSS flue gas recovery system, thermal efficiency can be increased by another 5%, total > 98%)

– Touch screen control (data can be easily transmitted to the site via BMS facility, stop, start, blowdown facility via built-in optional CERTUSS, run time can be set manually or remotely)

Function principle:

– By using the coil boiler principle, the CERTUSS technology for steam generation provides the highest safety, reliability and ready availability of high quality steam.

– Touchscreen control panel simplifies generator operation and control. All configurations and settings for the steam pressure are located here.

– Preheated feedwater is delivered to the generator in approximately 30 minutes. The inlet water temperature can be increased to 85°C to 96°C. The high temperature releases oxygen from the water, reducing the risk of oxygen corroding metal piping.

– Feed water is supplied to the boiler through the heat exchanger coil. Then it starts with water turning into steam.

– The fastest response time modular built-in burner that provides precise steam pressure control to 0.01 BARG (gauge).

– The insulation material directs the combustion air from the top of the generator through the casing and from within the casing to the inner second casing.

– Combustion air intake and fans draw warm air through a triple layer insulation system to preheat combustion air and keep the enclosure cool.

– Once the steam is generated, it leaves the generator through the steam outlet and is then ready for use.

– The flue gas outlet is connected to the chimney with or without a flue gas recovery system

– Deposits are flushed out through the coil drain valve. When the pressure is too high, the safety overflow valve will automatically open to discharge excess steam.

The Universal TC Series, our highest performing steam solutions. We offer dual fuel burners for various fuel types including LPG, Natural Gas, No. 2 Oil or Natural Gas and No. 2 Motor Oil. TC generators can meet constant as well as fluctuating high steam demands. Touchscreen controls are easy to operate and provide a bundle overview of current pressure and configuration. All of our generators offer short heat-up times and remote operation

德國 Certuss original technical explanation

| Construction series | 4 | 5 | 6 | 7 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| production capacity | Steam output (kg/h) | 500 – 650 | 700 – 850 | 1000 – 1300 | 1500-1800-2000 | ||||||||

| Heating energy kW | 328 – 427 | 459 – 557 | 656 – 853 | 984 – 1180 – 1320 | |||||||||

| Rated load kW | 364 – 485 | 510 – 619 | 728 – 947 | 1093-1311-1457 | |||||||||

| work pressure | working pressure bar | 8-14-18-22-29 | 8-14-22-29 | 8-14-22-29 | 8-14-22-29 | ||||||||

| Maximum allowable overpressure bar | 10-16-20-25-32 | 10-16-25-32 | 10-16-25-32 | 10-16-25-32 | |||||||||

| Dimensions (mm) | height/width/depth | 1980 / 930 / 1600 | 2290 / 1160 / 1870 | 2535 / 1260 / 2125 | 2675 / 1380 / 2310 | ||||||||

-可調壓差式 蒸汽專用.jpg)

-可調壓差式.jpg)

-固定壓差式 水、油、空氣.jpg)

.jpg)

.jpg)

.jpg)

.jpg)