PRODUCT INFORMATION

Zeomangan Manganese Sand – Removes Iron and Manganese (Made in Taiwan)

- front page

- product

- water treatment

- Removal of heavy metals (groundwater)

- Zeomangan Manganese Sand – Removes Iron and Manganese (Made in Taiwan)

Product Information

- heat treatment

-

water treatment

- Arsenic remover

- Desulfurizer

- Deaerator

- Water softener (calcium and magnesium ion removal)

- Carbon filter (removes odor and residual chlorine)

- Sand filter (removal of suspended impurities)

- Iron remover (removal of iron and manganese ions)

- RO water purifier

- Pre-backwash filter

- UV ultraviolet sterilizer

- Ion exchange resin

- reverse osmosis membrane tube

- quick filter

- Various tanks for water treatment

- Various application filter media

- 美國 Clack Clark control valve

- 美國 Fleck Control Valve

- 美國 Pentair Control Valve

- 美國 Autotrol Control Valve

- Runxin Control Valve

- Injection treatment

- Technology Development Department

-

brand

- Demo brand

- US DOW

- IDEX USA

- US CLACK

- EMERSON, USA

- American PENTAIR

- SIEMENS Germany

- American PULSAFEEDER

- Denmark DANFOSS

- Thailand HAYCARB

- France SUNTEC

- UK PUROLITE

- Japanese NOP

- Japan OLYMPIA

- Japan KATSURA

- BRAHMA, Italy

- SAGINOMIYA

- HONEYWELL

- AZBIL (YAMATAKE)

- OLTREMARE

- NIPCON

- TROCHOID

- domestic

- EGO

- KATO

- LECIP

- ATS

- JACOBI

- ETATRON

- WAVE CYBER

- BOSCHINI

- NIPPON

- WL

- CASH ACME

- YAZAKI

- RUNXIN

- About | Contact

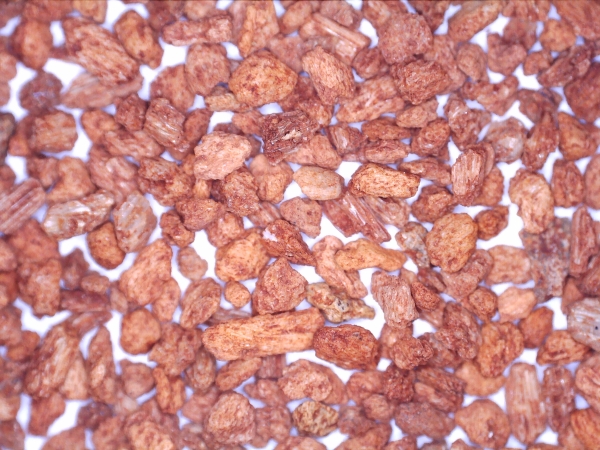

Zeomangan Manganese Sand – Removes Iron and Manganese (Made in Taiwan)

- Remove iron and manganese ions from water: Manganese sand uses its strong oxidizing ability to oxidize the divalent iron and divalent manganese ions in the water into trivalent iron and trivalent manganese ions, causing them to precipitate, and then separate them through adsorption and filtration of the manganese sand layer, thereby achieving the effect of purifying the water quality.

- Removal of hydrogen sulfide (H₂S): Manganese sand can also adsorb and remove hydrogen sulfide in water.

- catalytic oxidation: Manganese sand itself has catalytic oxidation ability and can accelerate the oxidation reaction process in water.

- Groundwater and tap water treatment: Used when the iron and manganese content in groundwater or tap water exceeds the standard to solve the red and black water problems.

- Industrial water treatment: Widely used in water treatment systems in the power, oil refining, food, printing and dyeing, papermaking, electronics, pharmaceutical and other industries.

- Aquariums and aquaculture: Used for water filtration in aquariums and fish and shrimp farming to maintain good water quality.

- Regular backwashing: The sediment produced during the filtration process needs to be discharged through backwashing to maintain the filtration efficiency of manganese sand.

- Potion Regeneration: In order to maintain its oxidizing ability, manganese sand needs to be regenerated regularly using reagents such as potassium permanganate (KMnO₄).

Manganese sand (manganese zeolite) is made by repeatedly mixing and calcining a solid, porous base material with high-grade manganese compounds. It can be used as a catalytic converter for soluble iron and manganese cations in deep well water. Furthermore, due to its inherent porosity, manganese sand (manganese zeolite) can also remove suspended solids from the water, making it suitable for use in both closed pressurized filtration systems and open gravity filtration systems. Generally, when iron and manganese levels in underground well water exceed specified limits, the water will appear red or black, necessitating the urgent need for iron and manganese removal. Manganese sand (manganese zeolite) offers highly efficient iron and manganese removal capabilities, resolving water quality issues.

Technical explanation

| Effective particle size | 0.6 – 0.7mm |

| Uniformity factor | < 1.7 |

| true specific gravity | 2.5 – 2.6 |

| fake specific gravity | 1.0 – 1.1 |

| Manganese content | > 60mg per 15g |