PRODUCT INFORMATION

Etatron – AD Dosing Machine (Dosing Pump)

- front page

- product

- Mechanical diaphragm injection

- Injection treatment

- Etatron – AD Dosing Machine (Dosing Pump)

Product Information

- heat treatment

-

water treatment

- Arsenic remover

- Desulfurizer

- Deaerator

- Water softener (calcium and magnesium ion removal)

- Carbon filter (removes odor and residual chlorine)

- Sand filter (removal of suspended impurities)

- Iron remover (removal of iron and manganese ions)

- RO water purifier

- Pre-backwash filter

- UV ultraviolet sterilizer

- Ion exchange resin

- reverse osmosis membrane tube

- quick filter

- Various tanks for water treatment

- Various application filter media

- 美國 Clack Clark control valve

- 美國 Fleck Control Valve

- 美國 Pentair Control Valve

- 美國 Autotrol Control Valve

- Runxin Control Valve

- Injection treatment

- Technology Development Department

-

brand

- Demo brand

- US DOW

- IDEX USA

- US CLACK

- EMERSON, USA

- American PENTAIR

- SIEMENS Germany

- American PULSAFEEDER

- Denmark DANFOSS

- Thailand HAYCARB

- France SUNTEC

- UK PUROLITE

- Japanese NOP

- Japan OLYMPIA

- Japan KATSURA

- BRAHMA, Italy

- SAGINOMIYA

- HONEYWELL

- AZBIL (YAMATAKE)

- OLTREMARE

- NIPCON

- TROCHOID

- domestic

- EGO

- KATO

- LECIP

- ATS

- JACOBI

- ETATRON

- WAVE CYBER

- BOSCHINI

- NIPPON

- WL

- CASH ACME

- YAZAKI

- RUNXIN

- About | Contact

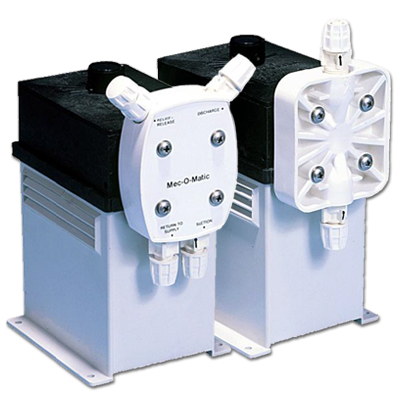

Etatron – AD Dosing Machine (Dosing Pump)

Quantitative pump (pump) / dosing machine: Diaphragm metering pump is a kind of reciprocating pump, which is developed by using the characteristics of fixed flow of reciprocating pump. Install a diaphragm between it and the liquid-contacting end, and use oil pressure to build pressure. It is characterized by high precision, no matter when the pump is stationary or running, the stroke length can be continuously adjusted within the range of 0%-100%, which is suitable for various fluid and pressure conditions. Diaphragm quantitative pumps are widely used in various industrial processes such as petrochemical, chemical, electric power, water treatment, and pharmaceuticals to quantitatively transport various chemical additives.

- – Small dosing pump, used for water treatment, process dosing, strong stability and durability

- – The diaphragm is made of TEFLON (Teflon) on the surface and artificial rubber on the back

- – 義大利 process motor is durable and stable

- – The dosing amount can be controlled by manually adjusting the stroke length of the diaphragm, and the dosing frequency is fixed

Technical teaching:

Quantitative pump (pump) / dosing machine: Diaphragm metering pump is a kind of reciprocating pump, which is developed by using the characteristics of fixed flow of reciprocating pump. Install a diaphragm between it and the liquid-contacting end, and use oil pressure to build pressure. It is characterized by high precision, no matter when the pump is stationary or running, the stroke length can be continuously adjusted within the range of 0%-100%, which is suitable for various fluid and pressure conditions. Diaphragm quantitative pumps are widely used in various industrial processes such as petrochemical, chemical, electric power, water treatment, and pharmaceuticals to quantitatively transport various chemical additives. Technical explanation

| Dosage | 10 to 123 L/Hr(50Hz) |

| spit out pressure | 4 to 6 Bar |

| power supply | Three-phase 230-400V 50Hz, 275-480V 60Hz, TEFC, IP55 Single-phase 110V 60Hz, 230V 60Hz |

| Wetted material | Provide 316SS, PVC, PP options |

| Optional | DC servo motor accepts 4-20MA signal to change motor speed |